CFR - CARBON FIBER RESEARCH

A COMPLETE CARBON FIBER LINE IN A RESEARCH-SCALE PACKAGE

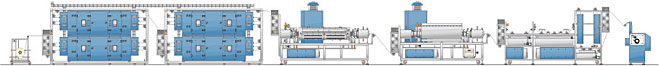

The Despatch CFR Series is a complete carbon fiber production line in a research-scale package. The CFR

Series allows users to run trials to study and test fibers and processes with the same quality of a full-scale

production line. The flexibility, functionality and size of the CFR make it an ideal solution for universities, laboratories,

new market entrants and existing manufacturers.

The CFR is available as a complete continuous production line or as independent subsystems, complete

with material handling and integrated or individual equipment control systems. Despatch offers world-leading

center-to-ends oxidation ovens, energy efficient LT and HT furnaces designed for ease of operation with

quick access to the muffle interior for easy cleaning. The Despatch surface treatment process provides uniform

electro-chemical etching. A minimum amount of fresh water and base electrolyte is used due to effective

recirculation systems. A sizing system provides uniform and constant distribution of size on the fiber. Fluid

concentration and levels are PLC controlled and size fluid is continually circulated and filtered while in use.

After surface treatment and sizing, non-contact dryers deliver uniform, low velocity airflow with variable temperature

control.

The integrated control system allows for accurate, centralized control of temperature and transport drive

speeds, higher levels of automation, and increased flexibility of the production line. The integrated control

system includes full data-logging and trending capabilities and enables the line to run at peak performance.