漆芸色々

管理人は、漆工芸について広く深い知識はありません。(キッパリ!!)うろおぼえの知識のみですが、参考程度にお読みください。

The webmaster does not have not much many knowledge about Japanese lacquer.

Although it is the right knowledge and does not become precocious, please read to a reference grade.

物の本によると、漆塗りを総称して髹漆(きゅうしつ)と呼ぶそうです。

漆塗りの技法を大別すると、素地・下地・加飾に別れ、

素地は、木地 布生地 和紙など漆が食いつけるものなら何でも、

下地には、蒔地(まきじ)本地(ほんじ)本堅地(ほんかたじ)など三種類に分けられ、

蒔地は、素地に直接塗付け木目を生かす塗り方で、代表的な物に春慶塗(しゅんけい)・目はじき塗・木地溜塗(きじためぬり)・摺漆(拭漆)などがあります。

本地 本堅地は、生漆にとの粉や地の粉を混ぜたもの数回塗りつけ研ぎ出しこれを下地とした物です。

加飾技法には蒔絵 螺鈿 漆絵 箔絵 沈金など数多くあります。

In Japan, the act which applies Japanese lacquer is called "KYUSITU."

A lacquered technique is divided into three kinds such as (foundation, a ground, and an ornament).

As long as it is the thing which can fix foundation (thing which made cloth and Japanese paper rival wood grain), etc. and Japanese lacquers, what kind of thing may be used.

Makizi Honzi Honkatazi etc. is divided into a ground by three kinds.

Makizi is the way of applying which applies a direct Japanese lacquer and shows a wooden pattern without making a ground.

By a typical thing, there is Syunkei coating Mehaziki coating Kizitame coating Suriurusi and Fukiurusi etc.

It calls Honzi and Honkatazi the thing which applied several times what mixed the Japanese lacquer with Tonoko (clayey powder) or ZInoko (powder of diatomite), and made it the ground.

There is many Makie Raden Urusie hakue Tinkin etc. in ornament technique.

Makie is the method of planting the powder of various metal on the surface and drawing a pattern and a picture.

Raden embeds on a ground the shellfish processed thinly, and expresses a pattern and a picture.

Urusie draws a picture with the lacquer which gave the color.

Hakue sticks with a lacquer the board of the metal made thinner than paper, and expresses a pattern and a picture.

Tinkin is the technique which applies a transparent Japanese lacquer on the picture and pattern which were drawn with metaled powder.

漆の乾燥

漆は、気温と湿度によって堅化乾燥します。

経験上ですが、気温15℃湿度60%で乾燥させた場合、

おおよそ8時間から12時間ぐらいで乾燥します。

それ以下の場合、漆の質にも依りますが24時間置いても乾燥しない場合もあります。特に湿度が低い時は、乾燥しません。

How to dry a Japanese lacquer .

With temperature and humidity, a Japanese lacquer becomes hard and it dries it.

Although it is on experience, when a Japanese lacquer is dried in the environment of 60% of humidity 15 degrees C of temperature, it takes 12 hours from 8 hours about.

In the case of not more than it, although it depends also on the quality of a Japanese lacquer, even if it applies for 24 hours, it may not dry

It does not dry, when there is little especially humidity.

筆の管理

筆や刷毛を使用した場合、その放置すると固まってしまうので、テレピン油でおおかたの漆を取り除いたら、

食用油で残りの生漆を、こそぎ取り、

多少油を残しそのまま保存してください。

次回使う時は、テレピン油で油を洗ってから使用します。

Management of the brush which applies a Japanese lacquer

When the brush is used, it will solidify, if it is left as it is.

Then, it shampoos its brush from tele pin oil, and removes a Japanese lacquer as much as possible.

And it includes cooking oil and is a spatula about the remaining Japanese lacquer. (thing of the form which does not damage hair) It takes so that it may rub.

In order to prevent dryness of the brush, it saves, where a little cooking oil is included.

When using next time, it uses it, after washing cooking oil from tele pin oil.

地の粉とは、

珪藻土の一種の黄土を蒸し焼きにし粉砕した粉末のことです。この地の粉と澱粉糊をまぜた漆を地漆と呼び、一辺地漆、二辺地漆、三辺地漆と進むごとに澱粉糊の割合が少なくなり地の粉の粒子が細かくなって行きます。

地の粉には、有名なところでは、輪島産と京都山科産とあり、

輪島産は硬くパサパサしている為、繋ぎに糊を加え、

山科産は、細かく粒子が整っており扱い易いそうです。

Zinoko

About a kind of ocher of diatomite, it is the thing of roast and the ground powder.

It calls Ziurusi the Japanese lacquer which mixed starch paste with this powder.

Whenever it progresses with one-side Ziurusi, two-side Ziurus, and three-side Ziurus, the quantity of starch paste decreases, and the particle of Zinoko becomes fine and goes.

The product from Wajima and the product from Kyoto Yamashina are in a typical place of production at Zinoko.

Since the product from Wajima is firmly friable, it adds starch paste to a connector.

Since the particle is finely ready, it is easy to use the product from Kyoto Yamashina.

漆の種類

The kind of Japanese lacquer .

生漆

漆の木から取れた樹液を、ゴミを取り除き、水分を調節した物。

Kiurusi

The thing which removed garbage for the sap which was able to be taken from the Japanese-lacquer tree, and adjusted moisture.

木地呂漆(透漆)

生漆を、くろめ なやしと言う工程を経て精製された物

Kiziro urusi or Suki urusi .

The thing refined through the process of Kurome and Nayasi in Kiurusi.

黒漆(黒呂色漆)

くろめとなやしの工程の前に鉄粉を混ぜウルシオールと反応させたもの。

Kuro urusi

The thing which mixed iron powder and was made to react with urushiol before the purification process of Kurome Nayasi.

つづく It continues.

ジャンル別一覧

人気のクチコミテーマ

-

-

- *雑貨*本*おやつ*暮らし*あんな…

- スーパーセール半額(スイーツ2)

- (2024-12-04 17:20:09)

-

-

-

- 運気をアップするには?

- 秘法講座で人生を謳歌出来ます!東京…

- (2024-12-03 23:47:30)

-

-

-

- 私なりのインテリア/節約/収納術

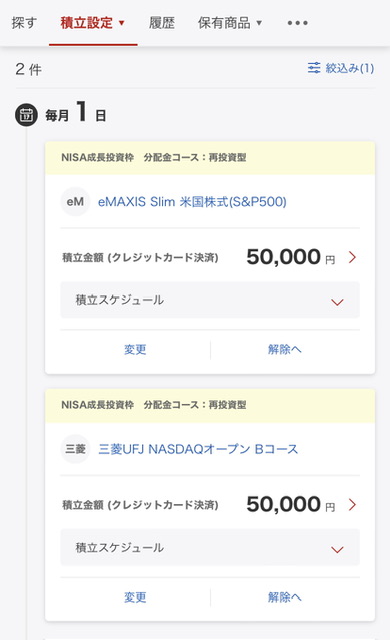

- 2024年新NISAの投資状況をお見せしま…

- (2024-12-03 23:41:05)

-

© Rakuten Group, Inc.